EBARA Corporation traces its origins to the foundation of the Inokuty Type Machinery Office in 1912. It has been taking on social and technological challenges with a spirit of passion and dedication (Netsu to Makoto) ever since. EBARA has developed and supplied to society many products, including fans and chillers, as well as pumps, becoming the first to produce many of those products in Japan.

History

1920s to 1940s: Building our foundations

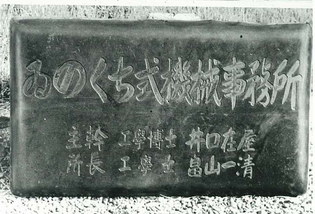

| 1912 | Founding of Inokuty Type Machinery Office Issey Hatakeyama founded the Inokuty Type Machinery Office with the goal of providing excellent products based on the centrifugal pump theory of world-renowned engineer, Dr. Ariya Inokuty.

|

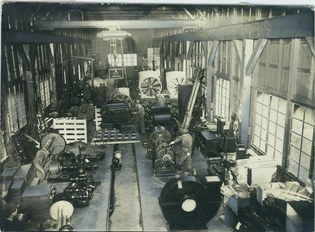

| 1914 | Establishment of first plant in Nippori, Tokyo |

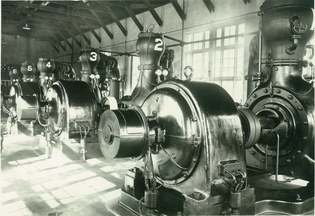

| 1916 | Order received for record-breaking large-scale pumps for Tokyo's Asakusa Tamachi pump station EBARA received an order for centrifugal pumps with a diameter of 1,140 mm, which was a record breaking size at the time. The pumps, each weighing over 20 tons, machined in a small local workshop that had no crane facilities. The painstaking efforts to complete the pumps involved chiseling the flange surfaces by hand and drilling holes with hand drills, as well as assembling and testing them on site. One of these pumps can be found on the premises of EBARA's head office as a monument symbolizing the spirit of "Netsu to Makoto (Passion and Dedication)."

|

| 1920 | Establishment of EBARA CORPORATION Inokuty Type Machinery Office changed its name to EBARA CORPORATION with the intention of expanding its business to include other products besides the Inokuty pump. At the same time, it built Japan's first plant for the exclusive manufacture of pumps. The Osaki Plant was established in Minami-Shinagawa, Shinagawa-machi, Ebara-gun, Tokyo.

|

| 1921 | Change of Trademark The EBARA logo was designed by combining the character “荏“ (the “E” in “EBARA”) with a pattern representing a centrifugal pump impeller.

|

| Start Manufacturing blowers and fans Sale of EBARA's first centrifugal blower | |

| 1924 | Production of the first axial-flow pump in Japan

Vertical axial pump with 400-mm diameter |

| 1925 | Launch of production of pumps in Japan for city water After making continuous efforts to promote the use of domestically-produced pumps, EBARA was given the opportunity to compare it with foreign products at the Yodobashi purification plant in Tokyo and successfully proved that the performance of its pumps was on par with that of the foreign products. It consequently launched domestic production of pumps for city water.

|

| 1930 | Completion of Japan's first production of centrifugal chillers

|

| 1931 | Completion Japan's first development of rapid filters for city waterworks |

| 1938 | Construction of new Haneda Plant and relocation of Head Office and manufacturing operations there

|

| 1941 | Establishment of Kawasaki Plant

|

| 1945~54 | Commitment to post-War reconstruction As a company that supports infrastructure, EBARA contributed to increasing the production of food, iron, and coal that were required for Japan's recovery. In addition to large-scale pumps for agriculture, EBARA conducted mass production and delivery of pumps and salt production equipment for the expansion of food production, to support the rebuilding of Japan after the War. |

1950s to 1970s: Meeting technological needs

During Japan's phases of economic recovery and rapid growth, EBARA faced an ever-increasing demand for advanced technologies from its customers. To respond to this demand, it strived to develop new products and technologies. It also made efforts to extend its business into other segments, such as the compressors and turbines business, by actively introducing advanced technologies. In addition, it worked to develop products and technologies necessary for social infrastructure such as water and sewerage systems, rainwater drainage facilities, and waste incinerators, all of which were required to create a better society to live in.

| 1956 | Introduction of technology through partnerships with other companies Establishment of EBARA-Infilco Co., Ltd. (50-50 joint venture with Infilco Inc. of the United States) for water treatment systems. A technical tie-up was executed with the Byron Jackson Pump Division of Borg-Warner Corporation of the United States for high pressure pumps (horizontal-barrel type). |

Launch of plan for expansion of small pumps business through standardization and mass production EBARA formulated a new concept for the mass production and sale of standard pumps, by standardizing the process of design and production of small pumps. The first standard pump was developed in 1956. Eventually, the product line was expanded to include multi-stage and submersible pumps.

|

|

| 1958 | Foundation of Ebara Griesheim, Ltd. (precursor of today's EBARA Densan) |

| 1961 | Entry into the waste treatment plant business EBARA entered the waste treatment plant business with the delivery of its first stoker-type waste incinerator. |

| 1963 | Receipt of order for first absorption chiller |

| 1964 | Full-scale entry into overseas markets and expansion of exports EBARA opened its first post-World War II overseas sales office in Bangkok, signifying the start of its expansion into overseas markets in line with the progress in trade liberalization. |

Establishment of Ebara Service Co., Ltd. Ebara Service Co., Ltd., was established to provide enhanced after-sales service for EBARA's products. After changing its name to Ebara Techno-serve Co., Ltd. in 2000, the company was merged into EBARA Corporation in 2012. |

|

| 1965 | Construction of Fujisawa Plant With the construction of its Fujisawa Plant, EBARA established Japan's first system for mass production of standard pumps. The Fujisawa Plant also began producing chillers the following year, and now manufactures a variety of product lines, including semiconductor-related devices.

|

| 1967 | Establishment of Ebara Koki Co., Ltd., (precursor of today's EBARA Fan & Blower Co., Ltd.) |

| 1968 | Entry into technical cooperation with Elliott Company of US for centrifugal gas compressors and steam turbines Entry into business of compressors for petroleum refining/petrochemical industry |

Sale of first supercritical pressure feed water pump produced in Japan

|

|

| 1973 | Foundation of Ebara-Byron Jackson Ltd. EBARA entered the field of circulation pumps for nuclear power plants. |

| 1975 | Establishment of EBARA's first post-War overseas production facility, Ebara Indústrias Mecánicas e Comércio Ltda. (precursor of EBARA BOMBAS AMÉRICA DO SUL LTDA.), in Brazil. |

Construction of Sodegaura Plant EBARA established the Sodegaura Plant in the city of Sodegaura, Chiba Prefecture, with the goal of expanding its compressors and turbines business.

|

|

| 1979 | Establishment of P.T. Ebara Indonesia as Southeast Asian production base for standard pumps. |

| 1981 | Establishment of Ebara International Corporation in the United States as North American base for pumps business. |

1980s to 2000s: Spreading our technologies

EBARA developed a new business segment centered on semiconductor production that supports advanced information society, as well as new products and technologies that meet the needs of society by saving energy and reducing the burden on the environment. As emerging nations have become the drive in the global economy, EBARA's business has continued to spread across the globe.

| 1984 | Establishment of current corporate logo With the transition from rapid to stable economic growth, the structure of society started to change. EBARA also undertook structural reforms designed to change old practices in an effort to respond to those social changes and created a new corporate logo as a way to refresh its corporate image. This logo is still in use today.  |

| Delivery of first unshredded refuse incinerator (TIF Incinerator) | |

| 1985 | Entry into precision machinery business

|

| Integration of Kawasaki Plant into Fujisawa Plant | |

| 1987 | Start of sales of absorption-type (dry) exhaust abatement systems |

| 1989 | Establishment of Ebara Italia S.p.A. (currently Ebara Pumps Europe S.p.A.) in Italy as European production based for standard pumps |

| Delivery of first internally circulating fluidized-bed boiler (ICFB) | |

| 1990 | Delivery of first bump plating system |

| 1991 | Establishment of Ebara Technologies Incorporated in the United States as North American base for precision machinery business |

| 1992 | Delivery of first CMP system |

| Establishment of EBARA QINGDAO CO., LTD. in China as base for boiler production | |

| 1994 | Merger with Ebara-Infilco Co., Ltd. and transition to three-business structure, namely Fluid Machinery and Systems, Environmental Engineering, and Precision Machinery |

| Establishment of Ebara Precision Machinery Europe in Germany | |

| 1995 | Establishment of Ebara Hai Duong Company Ltd. (precursor of today's Ebara Vietnam Pump Company Limited) as a production and sales base for pumps in Vietnam |

| 1996 | Establishment of Yantai Ebara Air Conditioning Equipment Co., Ltd. |

| 1997 | Establishment of Ebara Field Tech. Corporation as service company for Precision Machinery Business |

| Establishment of EBARA Precision Machinery Taiwan Inc. as a base for Precision Machinery Business in Taiwan | |

| 1999 | Establishment Shanghai Ebara Precision Machinery Co., Ltd. as based for Precision Machinery Business in China |

| 2000 | Integration of general machinery sales division and Ebara Service to establish Ebara Techno-serve Co., Ltd. |

| Acquisition of Elliott Company in U.S. as a wholly owned subsidiary | |

| 2001 | Establishment of Ebara Kyushu Co., Ltd. (precursor of today's Kumamoto District) |

| 2002 | Spin-off of compressors and turbines business into separate company, Elliott Ebara Turbomachinery Corporation |

| Spin-off of chillers business into separate company, Ebara Refrigeration Equipment & Systems Co., Ltd. | |

| 2003 | Establishment of Ebara Great Pumps Co., Ltd. as base for production and sales of API pumps in China |

| 2005 | Establishment of Ebara Boshan Pumps Co., Ltd. as base for production and sales of large-scale, high pressure pumps in China |

| 2006 | Establishment of Ebara Machinery (China) Co., Ltd., as base for production and sales of standard pumps in China |

| 2006 | Transition to three in-house company system |

| 2008 | Cumulative total of standard pumps produced at Fujisawa Plant reaches 15 million |

| 2009 | Reorganization of Environmental Engineering Business and integration into waste treatment plant business of EBARA Environmental Plant Co., Ltd. |

| 2010 | Establishment of new Futtsu Plant in Chiba Prefecture as global pump production base and transfer of functions of the Haneda Plant there |

| Establishment of joint venture, Ebara Engineering Service Co., Ltd. (currently Swing Corporation), between EBARA Corporation, Mitsubishi Corporation, and JGC Corporation, as global general water business company | |

| 2011 | Cumulative total of dry vacuum pumps produced at Fujisawa Plant reaches 100,000 units |

| Merger of Ebara Elliott and Elliot Company in U.S. | |

| 2012 | Merger of Ebara Technoserve Co., Ltd., Ebara Yoshikura Hydro-Tech Co., Ltd., and Ebara Environmental Technologies Hokkaido Co., Ltd. into EBARA Corporation |

| 100th anniversary celebration |

2010s to present: Surpassing 100 years

Further expanding into overseas markets and pursuing technological development as a global company that supports not only Asia but the entire world, EBARA continues in its day-to-day efforts to support society, industry, and everyday life for the next 100 years.

| 2014 | Establishment of Ebara Pumps Middle East FZE in the United Arab Emirates as a sales and service base for pumps in the Middle East. |

| 2015 | Cumulative total of compressors shipped by EBARA Elliott reaches 1,000 units |

| Acquisition of PT. Turbindo Chikara Surya (now PT. Ebara Turbomachinery Services Indonesia), an Indonesian company that provides maintenance services for rotating machinery | |

| Acquisition of Brazilian pump manufacturer, Thebe Bombas Hidraulicas S.A. (currently Ebara Bombas America do Sul Ltda.) | |

| 2016 | 30th anniversary of EBARA's precision machinery business |

| Completion of construction of new semiconductor manufacturing plant and maintenance service factory for dry vacuum pumps in Kumamoto District | |

| Establishment of Ebara Bombas Colombia S.A.S. as base for pumps business in Colombia | |

Cumulative total of CMP systems shipped reaches 2,000 units

|

|

| Establishment of new pump plant for Ebara Vietnam Pump Company Limited in Vietnam | |

| Establishment of Ebara Pumps Saudi Arabia LLC as based for pumps business in Saudi Arabia | |

| 2017 | Establishment of Corporate Brand Statement EBARA established a brand statement as its “Global One Message” that expresses the corporate attitude of the EBARA Group in the future of “Moving forward and higher” with an eye for competition and challenge.  |

| Establishment of Ebara Pumps South Africa (Pty) Ltd as a base for the pumps business in the Republic of South Africa | |

| 2018 | Number of cumulative dry vacuum pumps shipped from the Fujisawa Plant reaches 150,000 units

|

| 2019 | Establishment of new automated plant for dry vacuum pumps in Fujisawa District |

Launch of "eDYNAMiQ", EBARA's standard pump technology brand

|

|

| Establishment of Components Development and Innovation Center at Fujisawa District | |

| 2020 | EBARA Invests in Spiber Inc. and Forms Business Tie-Up in Field of Structural Protein Material Manufacturing |

| EBARA Forms Capital and Business Tie-Up with Regional Fish Institute, Ltd. | |

| Ebara Pumps Mexico, S.A. de C.V. Established in Mexico as Pump Sales and Service Base for North and Central America | |

EBARA Begins Sales of Solar Pumps in Brazil

|

|

| Knock Down Center Begins Operations in Vietnam EBARA CORPORATION has begun operations at Knock Down Center, which was established to carry out the assembly of standard pump products, in Vietnam in order to enhance the competitiveness of its Standard Pumps Business in overseas markets. |

|

| 2021 | EBARA acquired Çiğli Su Teknolojileri A.Ş. the parent company of Vansan Makina Sanayi ve Ticaret A.Ş., a Turkish pump manufacturer, and Vansan Makina Montaj ve Pazarlama A.Ş. |

| EBARA Begins Operations at Dry Vacuum Pump Overhaul Factory EBARA Precision Machinery Europe has begun operations at its new overhaul factory for dry vacuum pumps in Dresden, Germany. |

|

| EBARA Signs Sponsorship Agreement with Germany’s Boreal Light GmbH to Support Water Supply in Kenya | |

EBARA Completes Construction of HEFEI EBARA PRECISION MACHINERY CO., LTD. Overhaul Factory in China

|

|

| EBARA Begins Joint Research and Development with CellFiber | |

| 2022 | Transitioned from the First Section Exchange to the Prime Market of the Tokyo Stock Exchange |

| Certified the Eliminator in the cooling tower with U.S. LEED Certification, making EBARA REFRIGERATION EQUIPMENT & SYSTEMS the first Japanese manufacturer to do so | |

| Achieved a total of 3,000 shipments of CMP equipment | |

| Developed a new Flex-Op hydrogen compression solution at the Elliot Group | |

| Achieved cumulative shipments of 200,000 dry vacuum pump units at the Fujisawa factory | |

Began developing electric pumps for rocket engines |

|

| Established EBARA Pumps East Africa in Kenya | |

Published EBARA Group's Map of Engineering Talent and Strategic Table of Technological Capabilities |

|

| Acquired Hayward Gordon L.P. | |

| 2023 | Restructured the organization into five Companies based on Target Markets: Building Service & Industrial, Energy, Infrastructure, Environmental Solutions, and Precision Machinery |

| Successfully developed the world's first booster pump for liquid hydrogen | |

| Established EBARA CHINA CO., LTD. as the regional headquarters in China | |

| Established EBARA Pumps Europe S.p.A. Nordic Filial in Northern Europe | |

Developed a canned motor pump for liquid ammonia |

|

Developed the world's first hydrogen-fueled absorption chiller heater |

|

| 2024 | Received 500 orders for garbage treatment facilities and energy plants in Ebara Environmental Plant Co., Ltd. |

Successfully operated the canned motor pump using liquid ammonia |

|

| Opened the new service center in Indonesia | |

| Established the world's first R&D center to test commercial products equipped with full-scale test facilities for liquid hydrogen pumps using real liquid | |

Released pumps equipped with built-in PM motors and inverters |

|

| Successfully tested the centrifugal fluid of an electric pump for a rocket engine's cryogenic liquid | |

Constructed the new building for production (K3) at the Kumamoto Plant in EBARA Corporation |